Protective Sleeves

5.00 - 9.00 INR/Meter

Product Details:

- Application Protection for wires, cables, and pipes

- Use Industrial and electrical insulation

- Length Customizable (as per requirement)

- Type Protective Sleeves

- Material Polyester, Nylon

- Usage Protecting from mechanical abrasion, dust, and moisture

- Weight Lightweight

- Click to View more

X

Protective Sleeves Price And Quantity

- 5.00 - 9.00 INR/Meter

- 100 , , Meter

Protective Sleeves Product Specifications

- Protective Sleeves

- Polyester, Nylon

- Protecting from mechanical abrasion, dust, and moisture

- Lightweight

- Black, Grey, Blue, Yellow (varies as per requirement)

- Industrial and electrical insulation

- Protection for wires, cables, and pipes

- Customizable (as per requirement)

Protective Sleeves Trade Information

- 1000 , , Meter Per Week

- 1 Week

Product Description

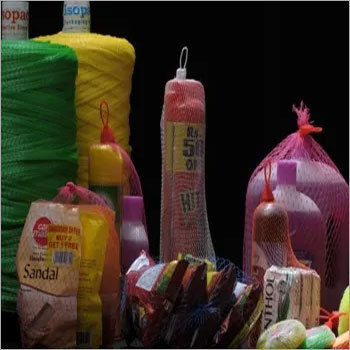

Protective Sleeves

By following latest industry norms, we are engaged in manufacturing, exporting and supplying an excellent quality Protective Sleeves. Our offered sleeves are manufactured with indigenous methodology and using quality assured raw materials at our sophisticated manufacturing unit. The provided sleeves are ideal for packaging various heavy as well as light goods and protect them from damage while transporting from one place to another. These Protective Sleeves are available in varied colors, thicknesses and can be availed at industry leading prices.

Features:

- Tear and heat resistance

- Strong and flexible

- Immaculate finish

- Durability

Versatile Diameter Range

Our protective sleeves are available in multiple diameters, ranging from 6mm to 50mm, making them suitable for a variety of cable, wire, and pipe sizes. This adaptability ensures a secure fit and effective protection tailored to specific requirements.

Exceptional Temperature and Chemical Resistance

These sleeves withstand temperatures up to 125C and demonstrate strong resistance to oils, solvents, and chemicals. Such resilience makes them ideal for demanding industrial and electrical insulation applications, maintaining performance even in harsh environments.

Customizable Lengths and Finishes

Select from smooth, woven, or braided surface finishes and order sleeves in rolls or customized cut lengths. The flexibility in dimensions and finishes provides ease of installation and matches unique project demands, ensuring optimal mechanical protection.

FAQs of Protective Sleeves:

Q: How do protective sleeves enhance the safety and lifespan of cables and pipes?

A: Protective sleeves shield cables and pipes from abrasion, dust, and moisture, minimizing physical damage and environmental wear. Their chemical and temperature resistance further prolongs asset life in demanding settings.Q: What process should be followed when installing these protective sleeves?

A: First, measure the diameter and required length of the sleeve. Choose the suitable finish and color, then slide the sleeve over the wire, cable, or pipe. Secure the ends if necessary. Rolls allow for tailored cutting during installation.Q: Where are these protective sleeves typically used?

A: These sleeves are commonly applied in industrial facilities, electrical wiring systems, and infrastructure projects to protect wires, cables, and pipes exposed to mechanical abrasion and harsh substances.Q: What benefits do braided and woven finishes offer compared to smooth finishes?

A: Braided and woven finishes provide enhanced mechanical strength and better resistance to dynamic movement, making them preferable for high-friction applications, while smooth finishes are suitable for basic protection needs.Q: Can the length and color of the sleeves be customized for specific projects?

A: Yes; both length and color can be customized according to project needs. Sleeves are available in black, grey, blue, and yellow, enabling easier identification and aesthetic coordination.Q: What is the primary material used for these protective sleeves and why?

A: Polyester and nylon are primarily used due to their high tensile strength, lightweight nature, and excellent resistance to chemicals, moisture, and abrasion, making them ideal for rugged industrial applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS